What is wire cutting?

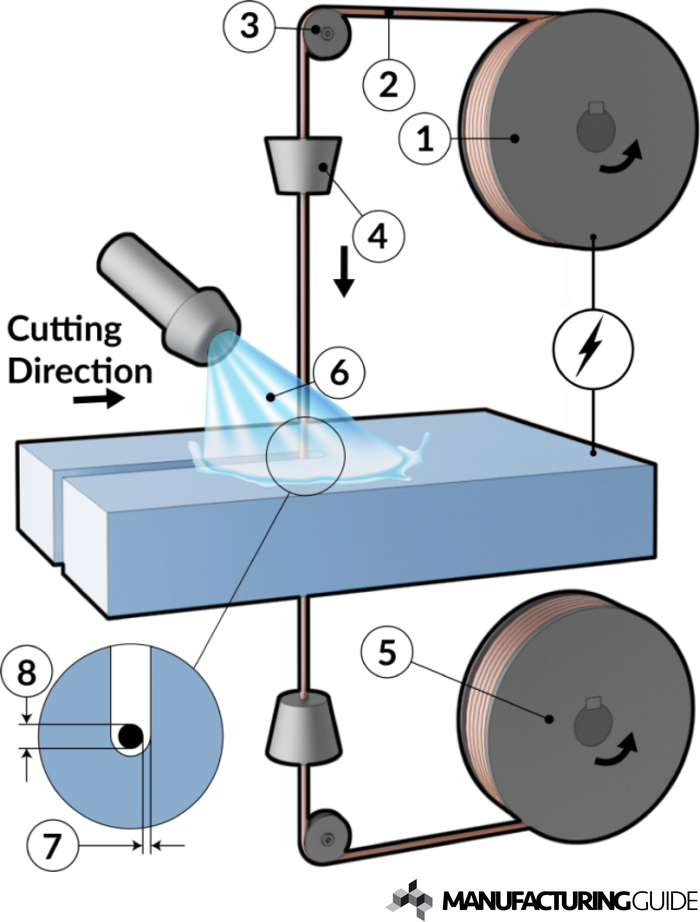

Wire cutting is , whic refers to the use of wire tools (such as metal wire, molybdenum wire, etc.) to cut raw materials (conductive materials), which belongs to the category of electrical processing.When the former Soviet Union Razalianko and his wife studied the phenomenon and causes of the damage of the switch contacts by spark discharge, they found that the instantaneous high temperature of the electric spark can melt and oxidize the local metal and be corroded, thus pioneered and invented the EDM method. The wire cutting machine was also invented in the former Soviet Union in 1960. Our country was the first country to be used in industrial production. At present, most of the wire cutting machine tools adopt a microcomputer control system with a high degree of automation.

Main application:

(1) Processing molds;

(2) Machining parts with fine structure;

(3) Machining parts with complex shapes;

(4) Processing hard conductive materials;

(5) Trial production of new products;

(6) Precious metal blanking.

Main feature:

Compared with traditional turning, milling and drilling processing methods, wire cutting has its own characteristics:

(1) Directly use 0.03-0.35 mm metal wires as electrodes, no specific shape is required, which can save electrode design and manufacturing costs;

(2) Regardless of the hardness of the workpiece material, as long as it is a conductor or semiconductor material, it can be processed, and the loss of the electrode wire is small, and the processing accuracy is high;

(3) It is suitable for the processing of small batches, complex shapes, single pieces and trial products, and the processing cycle is short;

(4) In WEDM machining, the electrode wire does not directly contact the workpiece, and the effect between the two is very small, so the deformation of the workpiece is small, and the electrode wire and fixture do not need too high strength;

(5) The working fluid adopts water-based emulsion, which has low cost and will not cause fire;

(6) It is not suitable for processing large-scale parts with simple shapes, nor can it process non-conductive parts.

Cutting process steps:

Prepare workpiece blanks, clamping tools, measuring tools, etc. before processing. If it is necessary to cut a workpiece with an inner cavity shape, or the process requires processing with a threaded hole, the blank should be pre-made with a threaded hole, and then follow the steps below:

(1) Start the machine tool power supply to enter the system and prepare the processing program;

(2) Check whether there are any abnormalities in each part of the machine tool, such as the operation of high frequency, water pump, wire tube, etc.;

(3) Wire threading, threading, and vertical alignment;

(4) Clamping the workpiece and aligning;

(5) For the wire, establish the starting position of cutting;

(6) Start the wire feed, turn on the working fluid pump, and adjust the nozzle flow rate;

(7) Adjust processing parameters;

(8) Run the processing program to start processing;

(9) Monitor the processing process, such as wire walking, discharge, working fluid circulation, etc. whether it is normal;

(10) Check whether the parts meet the requirements. If there are errors, they should be dealt with in time to avoid scrapping of processed parts.

Wire cutting processing:

Wire cutting products

1.OEM Stainless Steel wire cutting parts

2.Wire Cutting Tool Accessories

Scan to wechat: