-

Tungsten disulfide powder as lubricant coating Tungsten disulfide powder can be sprayed on the surface of the substrate by dry cold air under 0.8Mpa (120psi) pressure. Spraying can be performed at room temperature and the coating is 0.5 micron thick. Alternatively, the powder is mixed with isopropanol to apply a sticky substance to the substrate. At present, tungsten disulfide coating has been used in many fields, such as automotive parts, racing engine parts, aviation parts, bearings, shafts, deep-sea vehicles, cutting tools, blades, cutting tools, knives, mold release, high-precision bearings, Valve components, pistons, chains, etc. In addition, tungsten disulfide is also used as a colored brush in the carbon industry. It can also be applied to super-hard materials and welding wire materials. Tungsten disulfide can completely replace molybdenum disulfide, with comparable price, better quality and stronger performance. In addition, due to the extremely low friction coefficient (0.03 under dynamic and 0.07 under static) of tungsten disulfide powder, its application field is infinitely broad. Anything is possible if you want to get it.

-

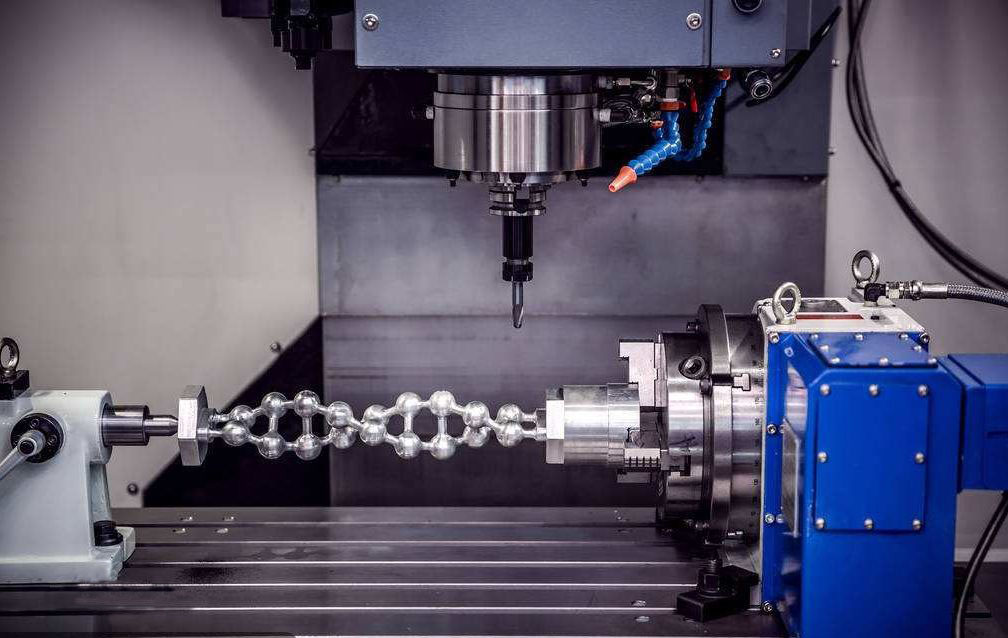

Which products can be processed by CNC machining center 1. Which products can be processed by CNC machining center Machining centers are suitable for complex machining, many procedures, and high requirements, which require the use of various types of ordinary machine tools and many tools, fixtures, and multiple machining and adjustment to complete the parts. The main objects of processing are box parts, complex curved surfaces, shaped parts, disks, sleeves, plate parts and special beads processing. 2. CNC machining center can process box parts Box parts generally refer to parts with more than one hole system, a cavity inside, and a certain proportion in the length, width, and height directions. Such parts are more commonly used in machine tools, automobiles, and aircraft manufacturing. Such parts generally require multi-position hole system and plane processing, with high tolerance requirements, especially strict shape and position tolerance requirements, usually through milling, drilling, expanding, boring, reaming, countersinking, tapping and other processes. There are many tools, it is difficult to process on ordinary machine tools, the number of tooling sets is high, the cost is high, the processing cycle is long, multiple clampings are required, the calibration is correct, and the number of manual measurements is large. The tools must be frequently changed during processing. The important thing is that accuracy is difficult to guarantee. For machining centers that process box-type parts, when there are many machining stations, parts that require multiple rotations of the table can be completed. Generally, horizontal boring and milling machining centers are selected. When there are fewer machining stations and the span is not large. When it is large, you can choose a vertical machining center to process from one end. Complex surface The CNC machining center occupies a particularly important place in the machining industry, especially in the aerospace industry. It is difficult or impossible to complete the complex surface using ordinary machining methods. In China, the traditional method is to use precision casting, and it is conceivable that its accuracy is very low. 3.CNC machining center can process complex curved surface parts Such as: various impellers, wind guide wheels, spherical surfaces, various curved forming dies, propellers and propellers of underwater vehicles, and some other free-form surfaces. These parts can be processed by machining centers. The more typical ones are: a.CNC machining center cam Cams, as the basic components of mechanical information storage and transmission, are widely used in various automatic machines. Such parts have various curved disk cams, cylindrical cams, conical cams, barrel cams, and end cams. Machining this kind of parts can choose three-axis, four-axis linkage or five-axis linkage machining center according to the complicated program of cam. b. Integral impeller of CNC machining center Such parts a...

-

CNC machining Generally CNC machining refers to computer-controlled precision machining, CNC machining lathes, CNC machining milling machines, CNC machining boring and milling machines, etc. Introduction CNC is also called computer gong, CNCCH or CNC machine tool. It is actually a name from Hong Kong. Later it was introduced to the Pearl River Delta in mainland China. It is actually a CNC milling machine. This is a new type of processing technology. The main job is to compile processing programs, that is, to turn the original manual work into computer programming. Of course, you need to have experience in manual processing. Determination of CNC machining routes NC lathe feed processing route refers to the path that the turning tool moves from the tool setting point (or fixed origin of the machine tool) until it returns to that point and ends the machining program, including the path of cutting processing and non-cutting such as cutting in and out Empty travel path. The feed route for finishing is basically performed along the contour of its parts. Therefore, the focus of determining the feed route is to determine the feed route for rough machining and empty stroke. In CNC lathe processing, the determination of processing routes generally follows the following principles. ① The precision and surface roughness of the workpiece to be processed should be guaranteed. ② Make the processing route the shortest, reduce the idle travel time, and improve the processing efficiency. ③ Simplify the workload of numerical calculation and simplify the processing procedures. ④ For some reusable programs, subroutines should be used. CNC pros and cons CNC machining has the following advantages: ① Reduce the number of tooling a lot, and do not need complicated tooling to process parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification. ② Stable processing quality, high processing accuracy and high repeat accuracy, adapt to the processing requirements of the aircraft. ③ The production efficiency is higher in the case of multi-variety and small batch production, which can reduce the time for production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the optimal cutting amount. ④ It can process complex profiles that are difficult to process by conventional methods, and even machining parts that cannot be observed. The disadvantage of NC machining is that the cost of machine tools and equipment is high, requiring a high level of maintenance personnel. CNC machining NC machining refers to machining performed by CNC machining tools. CNC index controlled machine tools are programmed and controlled by CNC machining language, usually G code. The NC machining G code language tells the NC machine tool which Cartesian position coordinates are used, and controls the tool feed speed an...

-

CONNECTORS A connector is a coupling device that joins electrical terminations to create an electrical circuit. Connectors enable contact between wires, cables, printed circuit boards, and electronic components. we attend customer design and manufacture an expansive portfolio of connectors that are engineered to reliably transmit data, power, and signal in the harshest environments, under the most extreme use. Our connectors are manufactured to reduce application size and power usage while enabling increased performance. Our audio and visual connectors offer enhanced board retention and EMI shielding. Our automotive connectors are build to withstand harsh conditions of highway and off-road transportation. Our card edge connectors and sockets support the current SDRAM and DDR memory generations and the new DDR2, DDR3, and DDR4 as well as FBDIMM generations.

-

Medical Equipment Metal Accessories Xiamen Zhonglida Machinery meets with more and more important success by working high-performance materials using CNC lathe machining,turning,milling of titanium. Attention to market demands and the liaison with research and development centres have allowed the creation of pieces that combine functionality and design.

-

Automobile Shock Absorber Accessories stainless steel material custom design drawing

-

Titanium Medical Parts Titanium is a transition metal often used in the aerospace, medical, and military industries. It is as strong as steel, but 40% lighter. Titanium is ductile and has a high melting point, making it ideal for extreme heat applications. Applications Titanium implants Titanium screw

-

Locating pins, parts involved in limiting the degree of freedom of objects, have certain applications in some mechanical motion equipment, mainly used for position determination in two-dimensional space Locating pin, using the workpiece hole as the positioning reference, is involved in the part that restricts the degree of freedom of the object, and controls the linear movement of the object in the three axial directions of X, Y, and Z, and six free movements around the rotational movement of X, Y, and Z degree. In a mold composed of two or more parts, a pin designed to accurately position two adjacent parts of the mold. Application When the machine body is formed by connecting multiple parts, and each part needs to maintain a precise position during processing and assembly, positioning pins should be used for positioning. For example, the split box body is composed of a machine cover and a machine base, and the processing of the bearing holes on it has higher precision requirements. Therefore, in the design, two positioning pins far apart should be set on the split surface to ensure Its processing and assembly accuracy. Classification and standards According to its structure, it can be divided into: small positioning pin, fixed positioning pin, replaceable positioning pin and positioning plug. Small positioning pin. Fixed positioning pin Reasonable structure of positioning pin. In order to maintain the accuracy of the relative position between the two parts after the certificate is installed, cylindrical pins or tapered pins are often used for positioning, so higher requirements for pins and pin holes. For the convenience of processing pin holes and pins, if possible, make the pin holes as through holes as possible, as shown in Figure (a).